Robot Control

Development details

We have experience in control development using the languages of various robot manufacturers!

(Yaskawa Electric's MotoPlus, Kawasaki Heavy Industries' AS, Fujikoshi.Co.Ltd.etc.)

We have a track record of developing homemade robot controls from scratch.!!

We have a track record of developing robot controllers and teach pendants similar to those of other manufacturers from scratch!

We offer the following development services for industrial robots and service robots.

Rescue robot (snake robot) simulation

- Motion controller connection

- Robot motion control using motion controller API

- Forward kinematics, inverse kinematics calculation

- Interference check, limit check, arrival check, singularity check

- Linear interpolation, circular interpolation

- Vibration control

- Calibration process

- Teaching path creation and editing

- Torque control

- Motion simulation

- Robot language conversion between multiple models

(example: KAWASAKI ⇒ MOTOMAN)

- Arm (manipulator) control

- Sensor control

- Robot self-propelled control

- Robot position and attitude control

- Tool control

- Double arm motion control

- Arm speed control

- AI function

- Business software development

- CAD application development

- Network system design / development

Development results

| 2018 | Development of a system utilizing an AGV (automated guided vehicle) |

| 2017 | Robot Japan Robot Association Granted

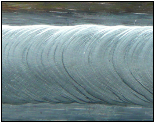

"Welding line tracking / control robot system" developed by system integrator training project to promote robot introduction ⇒ Sold as package software "WeldPath-1" |

| 2016~ | Pipe bending machine (Kawasaki'S robot (3 models), bending dedicated machine (2 models)) Simulation & CAM system development |

| 2016 |

|

| 2016~ | Development of molecular tracking proton therapy system |

| 2016~ | Precut 3D CAD system development |

| 2016 | VRC (Virtual Robot Controller) system development for robot manufacturers |

| 2016~ | Reactor accident handling business using industrial robots |

| 2015 | Building parts processing editing tool (for wood precut makers)

1. Overview In-house presentation application (using OpenCASCADE) for the development of 2D / 3D hybrid CAD application specialized for building material processing and editing |

| 2015 |

|

| 2015 | Development of direct teaching system.

By monitoring the torque information at the tip of the robot, the direction of the pushing force can be sensed, and by guiding the robot in that direction, position information is given with a button, and direct teaching is realized. |

| 2015 | Robot re-polishing work after detecting uncut parts and creating an automatic path in robot polishing work using a laser sensor. |

| 2014 | Obstacle interference / stop by torque control

While constantly measuring with the motion controller, the interference of obstacles (especially people) is checked according to the magnitude of the load (torque) coming from the motor, and if there is interference, it stops. After that, the operation restart button restarts the robot operation from that position. |

| 2013 | Development of polishing system using YAMAHA direct robot

Development of automatic polishing path creation system for YAMAHA direct robot (3 to 6 axes) in mold polishing work for automobile parts |

| 2013 | Development of pick and place system using HALCON (one camera) |

| 2013 | Development of robot automatic path creation system for electromagnetic noise

measurement

Developed an automatic path creation system for robot measurement to automatically measure electromagnetic noise in electrical and electronic equipment |

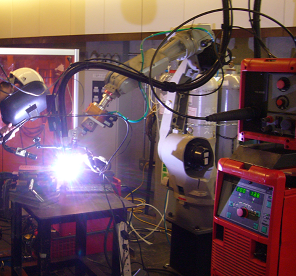

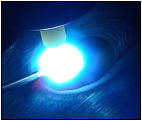

| 2011,2012 | Development of arc welding automation system for arc welding robots.

(arc monitoring with CCD camera) (supported by the Central Association of Small and Medium Enterprises in Tokyo) → Under development as WeldPath-2

Robot arc welding

Molten pond observation experiment |

| 2011,2012 | Development of a processing path creation system for construction wood (precut)

processing robots (FANUC large robots)

(shape processing (corner missing, triangular missing, gassho mortise, etc.), interference check, etc.) |

| 2011 | Vision sensor interlocking using 3D camera Shape recognition software interlocking

Development of in-control data (position, orientation) rewriting system in real time.

Development target robots: MOTOMAN, Kawasaki, NACHI robots |

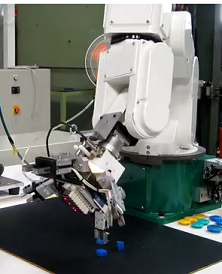

| 2009,2010,2011 | Vertical articulated 6-axis robot control for machine makers, application development

(assembly: turret use: visual inspection Insight system use) (4th and 5th axes become straight lines) |

| 2009 | Ministry of Economy, Trade and Industry Manufacturing SME Product Development Support

Project

Coating film thickness simulation, motion capture system development |

| 2003 |

Use of CIMETRIX robotics CAD CODE system processing management process manufactured by Cimetrix is a network, and process management at each node (base point of the network) ( Perform simulation) and cost control (tact time control). |

| 2001,2002 | Development of 6-axis manipulator system for reactor dismantling

Create a path by simulation using the robotics CAD CODE system manufactured by Cimetrix of the United States. The first time, while the plasma torch moves on the path without igniting the plasma, the position of TCP is confirmed with the camera, and if an obstacle occurs, it is stopped and avoided (path correction). The second time, the reactor is cut while igniting the plasma. |